Choosing the right identification tag is a critical decision that directly impacts the longevity and readability of your vital information. At Metal Image, our two most popular and durable options for harsh environments are 316 Marine Grade Stainless Steel and Sub-surface printed Anodised Aluminium. While both materials offer exceptional performance far exceeding standard labels, their strengths lie in different areas. The question isn’t which product is better, but rather: What environment or conditions must your product endure, and for how long? Read on as we compare these heavy-hitting materials to help you make an informed decision and select the perfect metal label or tag for your specific application.

316 Marine Grade Stainless Steel – Fibre Laser Marked

Stainless steel is the best option for extreme environments.

A relatively new addition to Metal Image ‘in house’. For years we have outsourced stainless steel labels for our customers. But with the market and technology evolving in 2020 we took it on ourselves and dipped a toe in with our very own desktop Fibre Laser. This gave us the ability to look after our existing customer base, create growth with new customers, and add to our incredible family of durable metal products which fall into our USP. We now run a much larger scale fancier fibre laser providing deeper darker etching options.

Stainless steel is the heaviest hitter at Metal Image, its functionality in the harshest of environments and heaviest of gauges makes it perfect for when the going gets tough. Learn more about stainless steel label applications.

All that said, nothing can take away from the ‘O.G’ in the Metal Image family.

You need stainless steel if your product will endure:

- Caustic washdown

- High impacts and abrasion

- Harsh, prolonged chemicals

- Intense, extended heat

- +50 year UV

Limitations of Stainless steel:

- Limited colour options

- Low to zero flexibility

- Costs more than aluminium

Why?

Why choose stainless steel for my metal plates, labels and tags?

Our fibre laser marked 316 Marine Grade Stainless Steel is almost indestructible. It withstands abrasion, washdown chemicals, intense heat and immeasurable UV.

Where?

Where is it recommended that stainless steel labels and tags be used?

Stainless steel excels in heavy industrial settings including contact food production, medical, marine, mining and chemical manufacture.

What?

What metal products are recommended to be made from stainless steel?

- Asset labels & tags

- Nameplates

- Rating plates

- Control panels

- Barcode tags

- Valve & hose tags

- Metal Labels

- Asset labels & tags

- Nameplates

- Rating plates

- Control panels

- Barcode tags

- Valve & hose tags

- Metal Labels

How?

What is the process? How are the 316 Marine Grade Stainless Steel products made?

Our stainless steel products are either deep etched and paint backfilled or fibre laser etched.

All that said, nothing can take away from the ‘O.G’ in the Metal Image family.

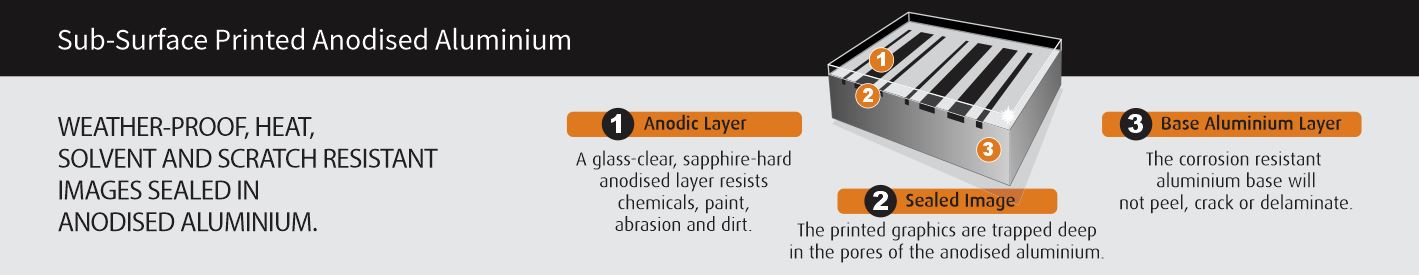

Sub-surface printed Anodised Aluminium

Choose anodised aluminium for harsh environments.

If you’re looking for a tough label that still withstands a hammering in its lifetime and looks beautiful while doing it then this is the product for you.

We have been producing this product since the days of printed photographic film. Exposed onto light-sensitive sheets of metal and processed through a series of steps to ‘seal’ the image in this product is the work horse which never fails to deliver. And while our technology has come a long way now through the use of laser imaging and specialised flatbed printers the end result is still the same. High resolution, highly durable, always readable images in brilliant aluminium.

Available in our most durable MetalPhoto (black/grey image) or full-colour AliChroma anodised aluminum has been used for asset tracking, compliance & rating, name plates and serial labels for over 40 years. Learn more about anodised aluminium.

There is nothing we can’t print on this product – just try us.

Choose anodised aluminium if your product will endure:

- Non-caustic chemicals

- Abrasion and impacts

- High to moderate heat

- Dirty, greasy, wet, coastal conditions

- +25 year UV*

*Metalphoto only

Benefits of Anodised Aluminium:

- Full range of colours

- Super flexible foil up to rigid

- Costs less than stainless steel

Why?

Why choose anodised aluminium for my metal plates, labels and tags?

Our anodised aluminium offers great value durability and anodic layer protection.

It withstands abrasion, most chemicals, high heat and long UV.

Where?

Where is it recommended that anodised aluminium labels and tags be used?

Anodised aluminium is perfect for general manufacturing, transportation, marine, aviation, agriculture, branding & POS, GS1 military and botanic identification.

What?

What printed metal products do you recommend to be made from aluminium?

- Rating, ID and name plates & tags

- Serial plates

- Brand labels

- Asset tags

- Valve & hose tags

- Control panels

- Business cards

- Barcode labels

How?

What is the process? How are your anodised aluminium products made?

Our anodised aluminium products are digital or photographic sub-surface imaged in your choice of full colour or black + greytone image.